Against the dual backdrop of rising global energy costs and carbon neutrality goals, industrial enterprises are increasingly demanding energy efficiency improvement technologies. As core equipment for motor system speed regulation and energy conservation, frequency converters (VFDs) are reshaping traditional industrial energy utilization patterns by enabling precise motor speed control through power electronic technology. Based on empirical research from "Energy Efficiency and Green Transformation: A VFD Case Study in an Industrial Facility," this article explores the technical advantages, energy-saving effects, and practical value of frequency converters in replacing traditional Y-Δ starting methods, providing actionable reference solutions for industrial green transformation.

I. Frequency Converters vs Y-Δ Starting: Energy Efficiency Comparison Experiment for Industrial Motors

In industrial production, asynchronous motors serve as core driving devices for equipment like fans and water pumps, with their starting and operating methods directly determining energy efficiency levels. For decades, Y-Δ starting has been widely adopted due to its low cost and simple structure, but this method has significant limitations: once initiated, the motor operates continuously at rated speed and cannot dynamically adjust according to load demands. Experimental data from a 37kW fan motor in an electrostatic powder coating plant shows that with Y-Δ starting, even when production only requires 70% air volume, the motor still runs at full speed, controlling air volume through damper throttling and causing substantial energy waste.

The application of frequency converters has completely transformed this scenario. In the experiment, after retrofitting the 37kW fan motor with a 45kW frequency converter, operating power decreased from 18.9kW (with Y-Δ starting) to 15kW while maintaining production efficiency, achieving an energy savings rate of 20.6%. More importantly, the frequency converter significantly improved power quality: reactive power reached 13.84kVAR with Y-Δ starting, but only 1.24kVAR with the frequency converter, greatly reducing line losses and transformer load while enhancing overall power system efficiency.

II. Core Energy-Saving Principles of Frequency Converters: Technical Breakthrough from Fixed-Speed Operation to Dynamic Speed Regulation

The energy-saving advantage of frequency converters stems from their precise control over motor speed. According to fluid machinery characteristics, the shaft power of fans and pumps is proportional to the cube of rotational speed—reducing speed by 10% can achieve approximately 27% energy savings. Experimental data verified this principle: when the frequency converter reduced motor operating frequency from 50Hz to 45Hz, active power decreased from 19kW to 15.1kW, demonstrating significant energy-saving effects.

Specifically, frequency converters achieve energy efficiency improvements through three technical pathways:

- Dynamic speed regulation matching load: Real-time adaptation to production air volume and flow demands, avoiding the "oversized motor" phenomenon. In the experiment, the frequency converter was flexibly adjusted within the 45-55Hz range, keeping the motor in the optimal efficiency zone;

- Power factor optimization: Compensation of reactive power through internal power electronic circuits—power factor was approximately 0.7 with Y-Δ starting, but improved to over 0.9 with the frequency converter;

- Soft starting reduces losses: Elimination of current surges during Y-Δ starting, reducing mechanical wear and extending equipment lifespan.

III. Economic Value of Frequency Converters: Dual Verification of Short-Term Payback and Long-Term Benefits

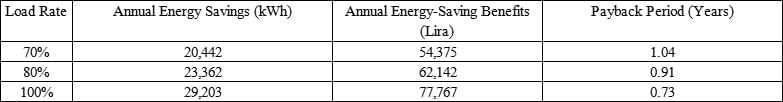

Economic analysis is crucial for industrial technology applications. In this experiment, the total investment of the frequency converter retrofitting project was approximately 56,677 Turkish Lira. At a 70% load rate, annual energy savings reached 20,442kWh. With an electricity price of 2.66 Lira/kWh, annual energy-saving benefits amounted to 54,375 Lira, resulting in an investment payback period of only 1.04 years. Economic performance under different load rates further confirms the investment value of frequency converters:

In the long term, frequency converters also reduce maintenance costs. Comparative experiments show that motors using frequency converters have 30% longer mean time between failures (MTBF) and approximately 25% lower annual maintenance costs than those with Y-Δ starting, due to stable operation and reduced wear.

IV. Harmonic Challenges of Frequency Converters: Problem Analysis and Solutions

While saving energy, frequency converters generate harmonic pollution due to switching operations of power electronic devices. Experimental monitoring found that the total harmonic distortion (THD) of the power grid was approximately 13% with Y-Δ starting, but increased to 30% with the frequency converter, with 5th harmonic current reaching 24.94A—potentially causing motor overheating and instrument measurement errors. The following measures can address this challenge:

1. Hardware Filtering Solutions

- Reactor configuration: Series AC reactors on the frequency converter input side can suppress over 50% of harmonic currents; DC reactors are recommended for models above 30kW to further reduce harmonic distortion;

- Specialized filters: Select frequency converters with RFI Class A1/B filters (like the model used in the experiment) to effectively reduce conducted interference and meet industrial power grid standards.

2. Operational Optimization Strategies

- Frequency setting: Avoid long-term low-frequency operation (below 20Hz) to reduce harmonic amplification risks;

- Distributed layout: Connect multiple frequency converters to different buses to reduce harmonic superposition effects.

V. Selection and Implementation Guide for Industrial Frequency Converters

Based on successful experimental cases, industrial enterprises should focus on the following key points when implementing frequency converter retrofits:

1. Model Selection Principles

- Power matching: Select models with 1.1-1.2 times the motor rated power; upsizing is recommended for heavy-load applications (e.g., 45kW frequency converter for 37kW motors);

- Function adaptation: Prioritize models supporting multi-speed regulation and PID closed-loop control to meet complex process requirements;

- Environmental adaptation: Choose IP54 or higher protection ratings for high-temperature and high-humidity environments, equipped with forced air cooling systems.

2. Installation and Commissioning Specifications

- Wiring requirements: Separate input and output cables; install output reactors for motor cables longer than 50 meters to reduce electromagnetic interference;

- Parameter setting: Set acceleration time according to load characteristics (30-60 seconds recommended for fans) and optimize V/f curves to ensure low-frequency torque;

- Testing verification: Use power analyzers (like the Chauvin Arnoux C.A.8331 used in the experiment) to monitor energy consumption and harmonic levels, ensuring compliance with design goals.

Conclusion: Frequency Converters Lead a New Paradigm in Industrial Green Transformation

This factory empirical study fully demonstrates that replacing traditional Y-Δ starting with frequency converters is an inevitable choice for industrial energy conservation. It not only achieves over 20% energy reduction but also improves production flexibility through dynamic speed regulation, with investment payback in approximately one year. Although harmonic challenges exist, they can be effectively controlled through proper filtering solutions.

In the context of global energy transition, frequency converters have evolved from simple energy-saving devices to core technical supports for industrial green development. By selecting appropriate frequency converter solutions, enterprises can reduce energy costs while contributing to sustainable development goals, laying a solid foundation for long-term competitive advantages in the low-carbon era.

If you're exploring frequency converter solutions for industrial energy efficiency upgrades, feel free to share your motor power, application scenario or technical questions below. Hengrong Electric CO., LTD. will respond promptly to tailor the right frequency converter solution for your needs!