In industrial electrical systems, harmonic pollution and reactive power imbalance often co-occur—harmonics generated by nonlinear loads intensify reactive power loss, while insufficient reactive power amplifies the impact of harmonics, forming a vicious cycle. As a core solution, reactive power compensation technology can not only dynamically adjust reactive power and optimize power factor but also cooperate with harmonic control equipment to suppress current distortion, becoming the key to ensuring grid stability. This article focuses on the in-depth integration of reactive power compensation and harmonic control, detailing technical paths, engineering cases, and selection points to provide references for enterprises to solve electrical system pain points.

I. Reactive Power Compensation: The Core Supporting Force for Harmonic Control

The harmonic problem in electrical systems is essentially a dual contradiction of "reactive power imbalance + current waveform distortion". Through accurately injecting or absorbing reactive power, reactive power compensation technology fundamentally improves the system operating environment and lays the foundation for harmonic control:

1. Reactive Power Compensation Stabilizes the "Foundation" First, Making Harmonic Control More Efficient

Nonlinear loads (such as frequency converters and arc furnaces) consume a large amount of inductive reactive power, resulting in a power factor as low as 0.7-0.8 and triggering voltage fluctuations, which further amplify the hazards of harmonics and cause the total harmonic distortion (THD) to exceed standards. Reactive power compensation devices (such as SVG and TSC) can balance reactive power in real time, increase the power factor to above 0.95, stabilize the bus voltage, and weaken the "breeding ground" for harmonics. Data from an automobile factory shows that without reactive power compensation, the THD reached 16%; after activation, the power factor stabilized at 0.98, and the THD synchronously dropped to 4.5%.

2. Pure Filtering Has Limitations, and Reactive Power Compensation Makes Up for Shortcomings

Traditional harmonic control only relies on filters, but filters cannot solve the problem of reactive power imbalance—for example, passive filters can filter out specific harmonics but may cause resonance due to system reactive power fluctuations; active power filters (APF) have strong dynamics but lack reactive power regulation capabilities. The combination of reactive power compensation and filters can achieve a "1+1>2" effect: APF is responsible for purifying the current waveform, and reactive power compensation devices (such as SVG) are responsible for stabilizing the power factor. The two cooperate to improve the harmonic control effect by more than 50%.

3. Dual Economic and Safety Benefits, Indispensable for Enterprises

The combination of reactive power compensation and harmonic control can bring direct value to enterprises: on the one hand, meeting the power factor standard can avoid electricity fines (a chemical plant was fined over 800,000 yuan annually, which was completely exempted after treatment); on the other hand, it reduces equipment loss due to harmonic overheating and extends the service life of transformers and capacitors (average extension of 3-5 years). At the same time, stable voltage and pure current can eliminate safety accidents such as equipment tripping and insulation breakdown caused by harmonics.

II. Reactive Power Compensation + Harmonic Control: Full-Process Technical Solution Design

A mature harmonic control system for electrical systems must take reactive power compensation as the core, covering the entire link of "equipment selection - capacity calculation - strategy optimization - installation layout" to ensure the implementation of control effects:

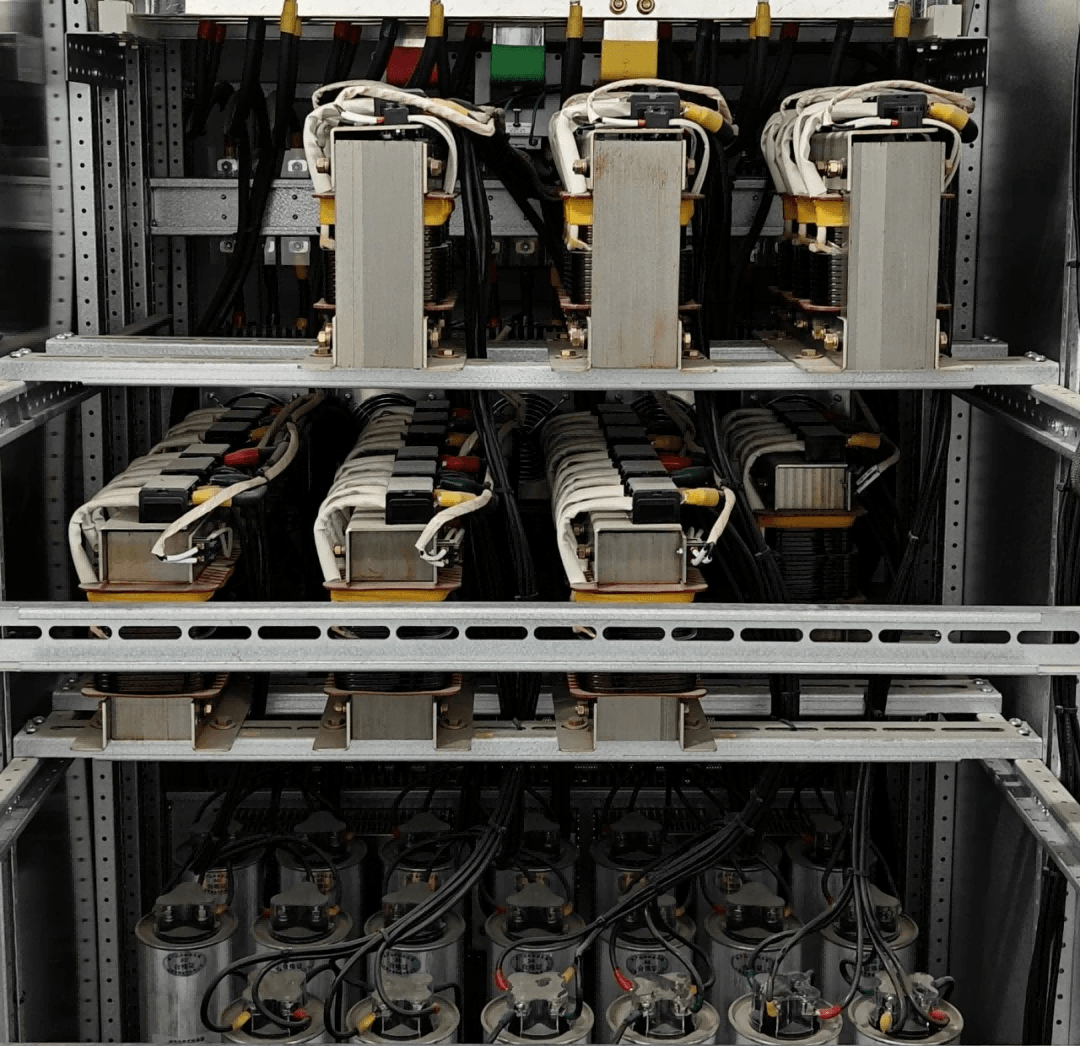

1. Accurate Selection: Matching of Reactive Power Compensation Devices and Filters

According to the system harmonic characteristics and load types, select matching reactive power compensation devices and filters. The core combination schemes are as follows:

- Ordinary industrial loads (motors, transformers): Thyristor Switched Capacitors (TSC) + passive filters (filtering 3rd, 5th, 7th harmonics), low cost, easy maintenance, and power factor up to 0.9 or higher;

- High nonlinear loads (frequency converters, rectifiers): Static Var Generators (SVG) + Active Power Filters (APF, filtering 2nd-50th harmonics), fast dynamic response (SVG response < 20ms, APF < 10ms), suitable for complex harmonic scenarios;

- Mixed load environments (coexistence of multiple types of equipment): TSC+SVG combination + hybrid harmonic filters (filtering 3rd-40th harmonics), high cost performance, and power factor stable at 0.95-1.0.

2. Scientific Calculation: Matching of Reactive Power Compensation Capacity and Capacitance Value

The key to the effect of reactive power compensation lies in the accurate calculation of capacity, which needs to be combined with grid voltage, load characteristics, and power factor targets:

- Core calculation logic: Reactive power compensation capacity is equal to the product of 2 multiplied by pi, multiplied by the system frequency, and then multiplied by the product of the capacitance value and the square of the grid voltage (where the unit of compensation capacity is kilovolt-ampere reactive, the unit of capacitance value is farad, the unit of grid voltage is volt, and the unit of system frequency is hertz);

- Example reference: For a 400V system with a load active power of 280kW, a pre-compensation power factor of 0.75, and a target of 0.98, it is calculated that a 1000 kilovolt-ampere reactive compensation capacity (model TSC-1000) needs to be configured, matched with a 500 ampere active power filter.

At the same time, the compensation method needs to be adjusted according to load characteristics: parallel capacitors for inductive loads and series capacitors for capacitive loads to avoid harmonic amplification caused by over-compensation or under-compensation.

3. Optimization Strategy: Upgrade of Reactive Power Compensation Capacitor Switching Rules

Traditional capacitor switching adopts a "fixed threshold", which is difficult to adapt to load fluctuations. The optimized strategy integrated with the dynamic needs of reactive power compensation can greatly improve stability:

- Switching criteria: When the actual compensation capacity of a certain capacitor is greater than the product of its rated capacity and the first suppression coefficient, the capacitor switch is opened; when the actual compensation capacity is less than the product of its rated capacity and the second suppression coefficient, the capacitor switch is closed (where the actual compensation capacity needs to be monitored in real time, the rated capacity is the factory calibrated value of the capacitor, and the two suppression coefficients are used to avoid system oscillation, which need to be set according to the load fluctuation amplitude);

- Core logic: Reserve load fluctuation margin to reduce the impact of frequent switching on the system. After application in a project, the number of capacitor switching times was reduced by 60%, and the THD fluctuation was controlled within ±1%.

4. Reasonable Layout: Planning of Installation Positions for Reactive Power Compensation Devices

The installation position of reactive power compensation devices directly affects the control efficiency. The recommended layout by scenario is as follows:

- Low-voltage side (400V): Install APF and TSC near nonlinear loads to specifically control local harmonics;

- Medium-voltage side (10kV): Install SVG behind the incoming cabinet to comprehensively adjust global reactive power and stabilize the bus voltage;

- Long-distance lines: Add reactive power compensation devices in the middle of the line to offset line inductive loss and avoid harmonic amplification along the line.

III. Engineering Case: Practical Effect of Reactive Power Compensation Technology in Harmonic Control

Taking a large-scale sewage treatment plant as an example, its electrical system suffered from severe harmonic pollution (THD 18%, power factor 0.75) due to the operation of multiple 280kW frequency converters, and the transformer frequently tripped due to overheating. After adopting the combined scheme of "SVG+APF+TSC" for reactive power compensation and harmonic control, the effect was remarkable:

1. Significant Improvement of Core Indicators

- Harmonic content: The peak harmonic current before treatment was 150 amperes, which dropped to below 30 amperes after treatment, and the filtering rate of key harmonics (5th and 7th) exceeded 92%;

- Total Harmonic Distortion (THD): Reduced from 18% to 4.2%, fully complying with the GB/T 14549-1993 standard (THD ≤ 5%);

- Power factor: Stabilized at 0.98-1.0, saving 520,000 yuan in electricity fines annually.

2. Significant Equipment and Safety Benefits

- Transformer temperature dropped from 85℃ to 65℃, noise reduced by 15 decibels, and the failure rate decreased from 2 times per month to 0;

- The service life of frequency converters was extended by 4 years, reducing maintenance costs by more than 350,000 yuan annually;

- The system voltage fluctuation was reduced from ±8% to ±2%, and no production interruption caused by harmonics occurred again.

IV. Key Points for Selection and Operation and Maintenance of Reactive Power Compensation Technology

1. Select on Demand to Avoid Blind Configuration

- Small and medium-sized systems (compensation capacity < 500 kilovolt-ampere reactive): Priority is given to TSC + passive filters with controllable costs;

- Large-scale, high nonlinear systems (compensation capacity > 1000 kilovolt-ampere reactive): SVG + APF combination is recommended for better dynamic performance;

- Remote areas/voltage-unstable scenarios: Add a voltage-monitoring module to interface with reactive power compensation devices for automatic voltage regulation.

2. Attach Importance to Post-operation and Maintenance to Ensure Long-term Effects

- Regular cleaning: Clean the heat dissipation channels of reactive power compensation devices and filters every quarter to avoid dust blockage affecting heat dissipation;

- Parameter calibration: Review the compensation capacity and filtering parameters every six months to adapt to load changes (such as adding compensation modules during peak seasons);

- Real-time monitoring: Use a harmonic analyzer (such as HARM-1000) to track THD and power factor in real time, and trigger reactive power compensation strategy adjustments when abnormalities occur.

3. Future Trend: Intelligent Upgrade of Reactive Power Compensation

The new generation of reactive power compensation technology is integrating the Internet of Things and AI algorithms to realize "automatic identification of harmonic types - prediction of load fluctuations - dynamic adjustment of compensation capacity", adapting to the differentiated needs of electrical systems of different scales and providing core support for the construction of smart grids.

V. Conclusion: Building a Clean Electrical System with Reactive Power Compensation as the Core

Reactive power compensation is not only a tool to improve power factor but also a "key" to solving harmonic pollution in electrical systems. Through the full-process scheme of "equipment selection - capacity calculation - strategy optimization - operation and maintenance guarantee", multiple goals of effective harmonic control, power factor optimization, and safe equipment operation can be achieved.

If your enterprise is facing problems such as excessive harmonics, substandard power factor, and frequent equipment failures, please feel free to inform us of the system voltage level, load type, and core pain points (such as THD value and electricity fine amount). HengRong Electric CO., LTD. will customize an exclusive "reactive power compensation + harmonic control" solution for you to help the electrical system operate safely, efficiently, and economically!