The Key Role and Application Trends of Variable Frequency Drives in Modern Industry

The Key Role and Application Trends of Variable Frequency Drives in Modern Industry

In today's global manufacturing and energy industries, energy conservation, automation, and intelligence have become irreversible development directions. With the continuous expansion of industrial scale, the usage of electric motors has increased significantly, and motor energy consumption accounts for the majority of total industrial energy consumption. How to reduce energy consumption while ensuring production efficiency has become a key factor in enterprise competition.

Against this backdrop, variable frequency drives (VFDs) have gradually entered public view, becoming the "core controller" of various industrial systems. Whether in automated production lines, urban infrastructure, transportation, or new energy fields, VFDs are silently playing a huge role.

1. What is a Variable Frequency Drive?

1.1 Definition and Working Principle

A Variable Frequency Drive (VFD) is an electrical device that controls the speed and torque of AC motors by altering the power supply frequency and voltage. Its core function lies in the "secondary processing" of electrical energy:

- Rectification: Converting alternating current (AC) to direct current (DC);

- Inversion: Converting DC back to AC with the required frequency and voltage via control circuits;

- Regulation: Flexibly adjusting motor speed in accordance with load demands to achieve efficient operation.

In this manner, VFDs not only precisely control motor operation but also significantly reduce unnecessary energy waste.

1.2 Status in Electrical Engineering

In traditional systems, motors are often directly driven at industrial frequency (50Hz/60Hz) with uncontrollable speed, resulting in high energy consumption and heavy wear. The application of VFDs has transformed this model, enabling motors to be flexibly adjusted according to working conditions to achieve "on-demand energy supply," which improves efficiency while extending equipment lifespan.

2. Main Types of Variable Frequency Drives

2.1 Voltage-Source Inverters

These VFDs control motor speed by adjusting voltage waveforms and are suitable for most small and medium-power motors. Their advantages include a relatively simple structure and high cost-effectiveness.

2.2 Current-Source Inverters

Current-source VFDs focus on current regulation, enabling them to better handle impact loads and high-power scenarios. They are widely utilized in heavy industries such as metallurgy and mining.

2.3 Vector Control VFDs

Vector control technology simulates the characteristics of DC motors, achieving independent control of torque and magnetic flux through mathematical models and feedback algorithms. These VFDs offer high precision and dynamic response, making them suitable for applications with strict speed and torque requirements, such as CNC machine tools and lifting equipment.

2.4 Differences Between Low-Voltage and High-Voltage VFDs

- Low-voltage VFDs: Commonly used for voltage levels of 400V~690V, covering most industrial applications.

- High-voltage VFDs: Suitable for voltages of 6kV~10kV or higher, often employed in high-power loads such as large water pumps, fans, and compressors.

3. Core Advantages of Variable Frequency Drives

3.1 Energy Conservation and Consumption Reduction

VFDs prevent motors from long-term full-load operation through "on-demand speed regulation." For instance, in pump and fan applications, reducing the motor speed by just 10% can save nearly 20% of energy consumption.

3.2 Prolonging Equipment Lifespan

Frequent start-stop operations of traditional motors cause mechanical and current impacts. VFDs enable "soft start" and "soft stop," effectively reducing mechanical wear and electrical shocks, thus significantly extending the lifespan of motors and related equipment.

3.3 Lowering Maintenance Costs

The extended equipment lifespan and reduced failure rates naturally lead to lower maintenance costs for enterprises. Additionally, VFDs are equipped with multiple protection functions, such as overcurrent, overvoltage, and overheating protection, further reducing operational risks.

3.4 Improving Power Quality

Modern VFDs are generally equipped with harmonic suppression and reactive power compensation functions, which can effectively enhance the power quality of the grid and reduce impacts on the power system.

4. Application Fields of Variable Frequency Drives

4.1 Industrial Automation

In manufacturing, VFDs are widely applied in machine tools, conveyor belts, compressors, and other equipment to achieve precise control and automated production. They are almost standard equipment in the metallurgy, chemical, and textile industries.

4.2 Municipal and Infrastructure

Water pump stations, air conditioning systems, elevators, and subway ventilation equipment all depend on VFDs. Through optimized control, these public facilities can reduce energy consumption while ensuring operational stability.

4.3 Energy Industry

In wind power and photovoltaic systems, VFDs are used for power control and grid connection to ensure the stable output of clean energy. Moreover, the oil and gas industry also makes extensive use of high-voltage VFDs.

4.4 Agriculture and Environmental Protection

In modern agricultural irrigation systems, VFDs adjust pump flow based on soil moisture to achieve water and energy savings. Sewage treatment plants also utilize VFDs to control the operation of blowers and pumps, thereby improving treatment efficiency.

5. How to Select the Right Variable Frequency Drive

When selecting a VFD, enterprises need to comprehensively consider the following aspects:

- Power and voltage level matching: Ensure the VFD matches the motor parameters;

- Operating environment: Factors such as temperature, humidity, dust, and electromagnetic interference;

- Control method requirements: Voltage-source VFDs for general applications, and vector control VFDs for high-precision needs;

- Brand and after-sales service: Choose brands with technical support and service guarantees to avoid post-operation and maintenance risks.

6. Industry Development Trends: Intelligence and Greenization

With the integration of digitalization and IoT technologies, VFDs are evolving toward intelligence and networking. Future VFDs will not only serve as motor drivers but also act as data collection and analysis nodes, enabling remote monitoring and predictive maintenance to support smart factories.

Meanwhile, global "dual-carbon" goals have driven green manufacturing, and energy-efficient VFDs will face a larger market. Whether in traditional industries, new energy, or smart city construction, the role of VFDs will become increasingly prominent.

7. Conclusion

From basic energy conservation to intelligent upgrading, VFDs have become indispensable key equipment in modern industrial and social operations. They have not only changed the operation mode of traditional motors but also created huge value for enterprises and society by improving efficiency, reducing costs, and optimizing energy structures. With the continuous advancement of technology in the future, VFDs will undoubtedly play a greater role in more fields, becoming an important engine for promoting sustainable industrial development.

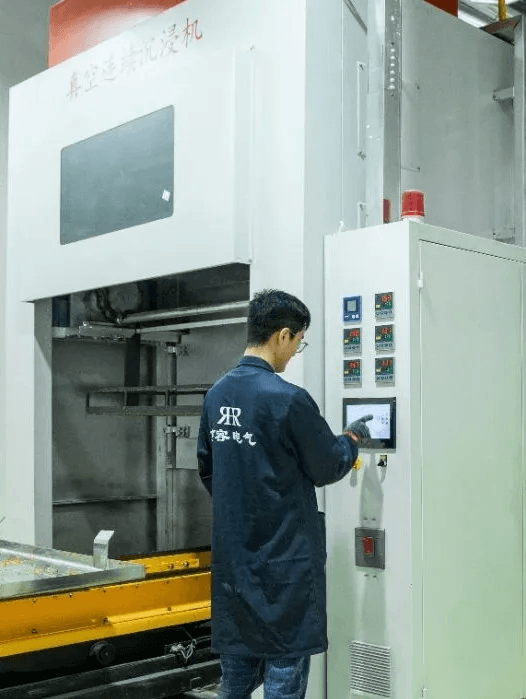

Hengrong Electric CO., LTD. offers VFD. Welcome to leave a message or call. We are always here to help you.