Medium-Voltage Reactor

Inductance Deviation: ±3%Ln (Rated Load)

Current Withstand Capacity: Fundamental: 1.05×In (long-term); Harmonic: 30%×In (continuous)

Insulation Class:Class H (180℃ withstand temperature)

Protection Level: IP66 (Standard Model)

Short-Circuit Withstand Capacity: 40kA/4s, Peak Current 100kA

Operating Noise: ≤65dB (at 1m Distance)

Operating Temperature Range/Anti-Seismic Level: -40℃~+120℃/Max. Class A (0.4g Acceleration)

Extreme-Resistant Medium-Voltage Reactor: Safe, Stable, Durable

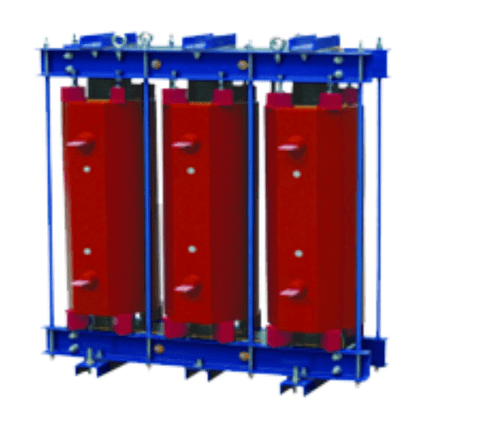

I. Product Overview

This medium-voltage reactor adopts a dry-type iron core three-phase integrated design, tailored for high-end applications including medium-voltage power distribution, new energy, and rail transit. Its core functions cover harmonic suppression, voltage stabilization, and power quality enhancement. Compliant with international standards IEC 289 and IEC 76, the product incorporates world-class design concepts, with comprehensive upgrades in structural precision, safety protection, and environmental adaptability. Boasting low loss and high linearity, it is suitable for 1-12kV networks, delivering efficient passive filtering and reactive power compensation solutions for industrial and infrastructure projects.

II. Core Structural Details

2.1 Iron Core Structure System

High-quality cold-rolled silicon steel sheets are adopted and processed via precision punching and stacking, effectively reducing hysteresis and eddy current losses. The operating temperature rise is ≤55K, and the noise level is ≤65dB (at 1m distance), outperforming industry benchmarks. The three-phase integrated iron core is positioned by non-magnetic components to avoid magnetic circuit deviation and vibration superposition. With excellent linearity performance, the inductance deviation is controlled within ±3% under rated current and 1.05 times fundamental current conditions, ensuring consistent filtering efficiency.

2.2 Winding and Insulation System

The winding employs H-class insulated copper foil (aluminum foil optional), manufactured by automatic winding equipment with a flatness error of ≤0.5mm. It forms an integrated structure through pre-baking, vacuum varnishing, and curing processes. The insulation layer adopts epoxy resin casting combined with vacuum impregnation, featuring an insulation resistance of ≥1000MΩ and no breakdown under 2500V AC power frequency withstand voltage for 1 minute, balancing insulation reliability and mechanical stability.

2.3 Mechanical Support and Installation Structure

The cabinet frame is constructed from 8mm aluminum-zinc coated steel sheet, with a bending stiffness of 200MPa, enabling it to withstand strong vibration and impact. Large-capacity models are equipped with high-damping rubber wheel brackets (damping ratio 0.2) and three-dimensional adjustable locking devices, suitable for installation and maintenance in narrow spaces. Anti-fall hooks ensure component displacement is less than 1.5mm under 0.5g acceleration, further enhancing structural stability.

III. Comprehensive Safety Protection System

3.1 Electrical Safety Protection

The short-circuit withstand capacity is 40kA/4s, with a peak current of 100kA. The segmented shielding design of the winding suppresses electromagnetic crosstalk, meeting the requirements of the ISO 11452-2 electromagnetic compatibility standard. Built-in arc protection and over-temperature monitoring modules trigger fault tripping within 0.1 seconds, effectively preventing electrical fires and equipment damage.

3.2 Intelligent Monitoring and Early Warning Protection

It is integrated with an industrial-grade intelligent monitoring unit compatible with mainstream industrial control platforms, which collects real-time data on vibration, temperature, and insulation status. Through LSTM neural network analysis, potential faults can be predicted 30 days in advance, reducing the failure rate to below 0.1 times per 1000 hours. It supports remote data transmission and local display, enabling predictive maintenance.

3.3 Mechanical Safety Protection

The cabinet achieves an IP66 protection level, adopting a composite sealing structure of double EPDM sealing rings and silicone sealant, combined with a pressure balance valve to stabilize internal air pressure. It offers three levels of anti-seismic design (Class C: ≤7 degrees, horizontal acceleration ≤0.15g; Class B: 8 degrees, 0.2g~0.3g; Class A: ≥9 degrees, 0.4g). Class A models meet the requirements of Nuclear Safety Shutdown Earthquake (SSE) and have passed AG5 nuclear-grade anti-seismic certification, adapting to various anti-seismic scenarios.

IV. Extreme Environment Adaptability Design

4.1 Temperature and Humidity Adaptability

Wide-temperature-range materials are used: silicone rubber components can withstand -40℃~+120℃, and NOMEX paper is resistant to 220℃, adapting to extreme low-temperature environments. The intelligent dehumidification system automatically adjusts humidity, and optional nitrogen-filled sealing controls internal humidity below 50%, improving insulation strength and adapting to high-humidity conditions.

4.2 Corrosion and High-Altitude Adaptability

Coastal-specific models adopt 316L stainless steel cabinets with a 1mm polyurea coating, showing no rust after a 1000-hour salt spray test; upgraded models can withstand 3000 hours of salt spray erosion. High-altitude models (up to 5000m) are optimized with nitrogen-filled sealing, with the busbar cross-sectional area increased by 15% to compensate for reduced current-carrying capacity due to thin air, controlling temperature rise at ≤60K and complying with GB/T 20626.3-2022 high-altitude equipment certification.

4.3 Vibration and Impact Adaptability

It has passed IEC 60068-3-3 and GB/T 13540-2019 certifications, with 0.5g acceleration resistance exceeding national standards. For high-frequency vibration scenarios such as subways, it complies with JIS C 4401 certification, with the circuit breaker switching time deviation ≤2ms and acceleration transmission rate controlled at 45%. Under 10-50Hz operating conditions, cabinet deformation is ≤1.2mm and component displacement is less than 0.8mm, ensuring long-term stable operation.

V.Application Scenarios and Customization Solutions

5.1 Typical Application Scenarios

New Energy: Filtering for photovoltaic and wind power converters, improving grid-connection stability.

Rail Transit: Subway/high-speed rail traction substations, adapting to vibration and temperature variation environments.

Industrial Manufacturing: Heavy-load scenarios such as metallurgy and the chemical industry, addressing harmonic pollution.

Infrastructure: Power distribution projects in extreme environments like coastal areas, high altitudes, and underground utility tunnels.

High-End Buildings: Data centers and commercial complexes, ensuring the operation of sensitive equipment.

5.2 Customization Services

Comprehensive customization services are available, covering materials (winding/cabinet material), performance (anti-seismic/protection level), scenarios (narrow cabithe net/extreme environment modification), and intelligent modules (monitoring/remote control). Structural parameters are optimized on demand to achieve precise system adaptation.

VI. Quality and Certification Assurance

The product has obtained CE, UL, IEC 61439-1, and domestic CQC anti-seismic certifications, complying with the ISO 9001 quality management system, and is delivered after 12 rigorous inspection procedures. The standard model comes with a 5-year warranty, while nuclear-grade and rail transit models offer an 8-year warranty. A professional technical team provides full-lifecycle services.