1. Introduction

In power systems, reactive power balance is crucial; imbalance can cause voltage drops, equipment damage, and system collapse, while also reducing power factor and increasing network losses. Devices like rolling mills and arc furnaces with frequent and intense reactive power changes worsen power quality, leading to voltage sags, flickers, and higher line losses.

Existing reactive power compensation devices have limitations: DSTATCOM enables dynamic continuous compensation but faces challenges in large-capacity design and high costs; TSC meets capacity requirements but cannot achieve continuous stepless compensation and has slow response. Additionally, traditional compensation methods (local and decentralized) suffer from cumbersome maintenance, low capacitor utilization, and frequent manual switching, leading to over-compensation or under-compensation. Thus, developing a low-cost, large-capacity dynamic reactive compensation topology and optimization methods is necessary.

2. Structure and Working Principle of HVC

The Hybrid Var Compensator (HVC) combines a small-capacity DSTATCOM and multiple TSC groups, integrating their advantages: DSTATCOM handles continuous reactive power adjustment and suppresses voltage fluctuations (continuous subsystem), while TSC provides large-capacity capacitive reactive power at low cost (discrete subsystem).

- Topology: HVC is parallel-connected to the low-voltage bus, with a DSP controller coordinating TSC switching and DSTATCOM's PWM signals.

- Compensation Principle: TSC performs coarse reactive power adjustment in stages, and DSTATCOM provides fine stepless adjustment. When reactive demand falls between n and n+1 TSC groups, n groups of TSC are activated, and DSTATCOM compensates for the remaining small capacity, achieving low-cost continuous compensation between maximum capacitive (I_Cmax) and inductive (I_Lmax) reactive current.

3. HVC Control Methods

The control system adopts a three-layer structure: execution level (TSC and DSTATCOM), reactive intelligent control level (fuzzy PI controller), and decision-making level (expert reasoning).

- Decision-Making Level (Expert Controller): Determines TSC switching groups and DSTATCOM's target current based on grid reactive power data. It uses 8 rules to decide the number of TSC groups to switch (p), considering factors like current reactive demand (I_qSTAT) and available TSC capacity.

- Reactive Intelligent Control Level (Fuzzy PI Controller): Regulates DSTATCOM by combining fuzzy control and PI control. Fuzzy adjusters optimize PI parameters (Kp, Ki) online based on deviation (e) and deviation change rate (ec), with 7 linguistic values (NB to PB) and triangular membership functions. Decoupling control separates active and reactive current loops to improve precision.

4. Two-Level Collaborative Optimization System

To achieve global optimization when multiple HVCs operate, a two-level collaborative system is proposed:

- System Composition: Lower-level HVC controllers collect grid parameters (via 485 bus) and perform local compensation; the upper-level computer analyzes multi-node data, calculates optimal compensation capacity via collaborative algorithms, and issues instructions to lower-level controllers.

- Optimization Algorithm: Focuses on minimizing power loss (objective function) with voltage constraints (U_min ≤ ξ_i U_max). Starting from the grid's end node, it uses dynamic programming to solve for optimal capacity at each node, considering line and transformer loss reductions. The algorithm ensures no local under-compensation or over-compensation by propagating optimal strategies forward from the end node.

5. Experimental Results

A low-cost dynamic energy-saving system was developed for a smelter, with the following results:

- System Design: Lower-level controllers (based on DSP2407) handle reactive adjustment, safety monitoring, and data communication; the upper-level industrial computer (using Delphi7.0) realizes global optimization via dynamic programming.

- Application Effects: When inductive loads start suddenly, HVC stabilizes 380V bus voltage (from 200V to ~232V) and improves power factor. Compared with single-point optimization, collaborative optimization increases the total power factor from 0.87 to 0.96, reducing line loss by 20.1% and annual energy savings by 190,000 yuan (vs. 130,000 yuan with single-point optimization).

6. Conclusion

The proposed HVC integrates DSTATCOM's continuous adjustment and TSC's large-capacity advantages, reducing costs while ensuring dynamic performance. The two-level collaborative optimization algorithm achieves global reactive power optimization in multi-node grids. Field tests in a smelter validate the system's superiority in energy saving and power quality improvement, with potential applications in high-voltage distribution networks.

Keywords: Dynamic var compensation; fuzzy-PI control; expert judgment; collaborative optimization; low cost

Hengrong Electric Co., Ltd.

We specialize in providing high-efficiency reactive power compensation and power quality optimization solutions. With over 20 years of industry experience, our products excel in enhancing grid efficiency, reducing energy consumption, and ensuring system stability.

Our core products and services include:

Low-voltage Reactive Power Compensation and Power Quality Optimization:

Self-healing Capacitors:

Improve power factor, optimize grid power quality, and extend equipment lifespan with self-healing functionality.

Increased Safety Capacitors:

Designed for hazardous environments with combustible gases, providing high safety and explosion-proof features.

Tuned Reactors:

Effectively absorb grid harmonics, improve voltage waveform stability, and protect capacitors.

Composite and Thyristor Switches: Reliable capacitor switching devices with no inrush current, low noise, and stable operation.

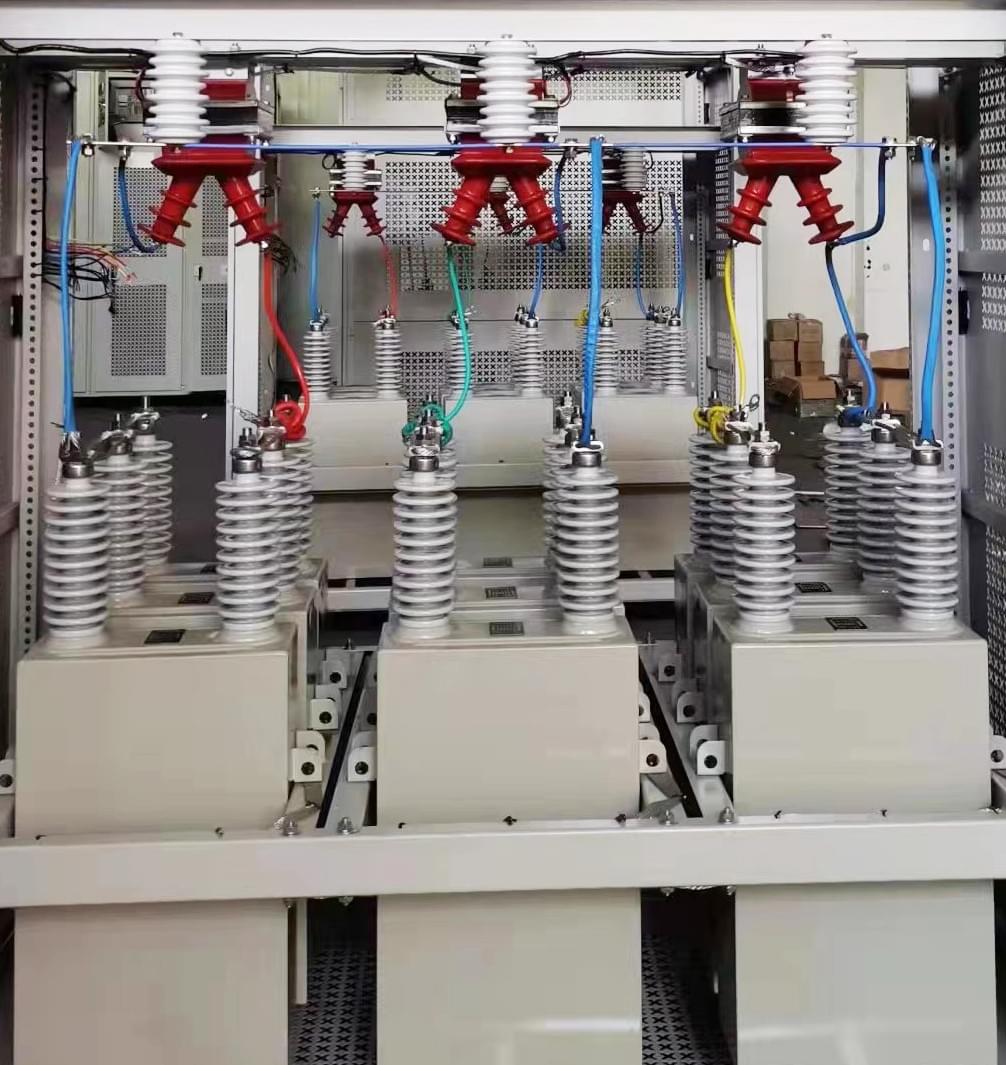

High-voltage Reactive Power Compensation Solutions:

High-voltage Capacitors and Reactors: Enhance high-voltage grid stability, effectively compensate reactive power, and suppress harmonics.

Power Quality Governance:

Active Power Filters (APF):

Eliminate harmonics, improve power quality, and ensure system stability.

Static VAR Generators (SVG):

Provide dynamic reactive power compensation with fast and smooth system response.

Smart and Customized Solutions:

Offer smart power quality management controllers and intelligent compensation devices that adapt to complex grid environments, ensuring optimal operation.

Why Choose Hengrong Electric?

Industry Experience: We have extensive experience in power quality optimization, having delivered reliable solutions for numerous clients across various industries.

Customized Services: We provide tailored solutions based on specific client needs, ensuring the maximum benefits for every project.

Technical Assurance: Our products are internationally certified and feature advanced technology, ensuring high efficiency, reliability, and long-term stability.