Introduction: Box-Type Substations and SVG in the Smart Grid Era

Driven by the goals of carbon neutrality and energy efficiency, Smart Grid development is accelerating worldwide. Enterprises and industrial parks now demand higher reliability and efficiency from their power distribution systems. As a key component in modern distribution networks, the box-type substation has become widely adopted due to its compact structure, small footprint, and quick installation.

However, during operation, the presence of inductive loads such as motors and frequency converters often causes the power factor to drop. A low power factor leads to wasted energy, increased line losses, reduced supply quality, and even penalties on electricity bills. To achieve true energy saving and consumption reduction, the deployment of SVG (Static Var Generators) has become the best solution.

Power Factor and Reactive Power Compensation: The Key to Energy Saving

The power factor is a critical indicator of how efficiently electrical energy is utilized. A low power factor means that a large portion of the supplied power is reactive, which increases line losses, overheats equipment, and shortens transformer lifespan.

Traditional reactive power compensation usually relies on capacitor banks. However, in scenarios with low load or rapidly fluctuating loads, capacitor banks face several challenges:

- Frequent switching and inaccurate compensation;

- Over-compensation or under-compensation issues;

- Resonance with the grid, leading to new power quality risks.

By contrast, SVG Static Var Generators—as an advanced device in the Smart Grid—provide fast, flexible, and precise compensation, making them the mainstream choice for improving power factor and optimizing power quality.

How SVG Static Var Generators Work

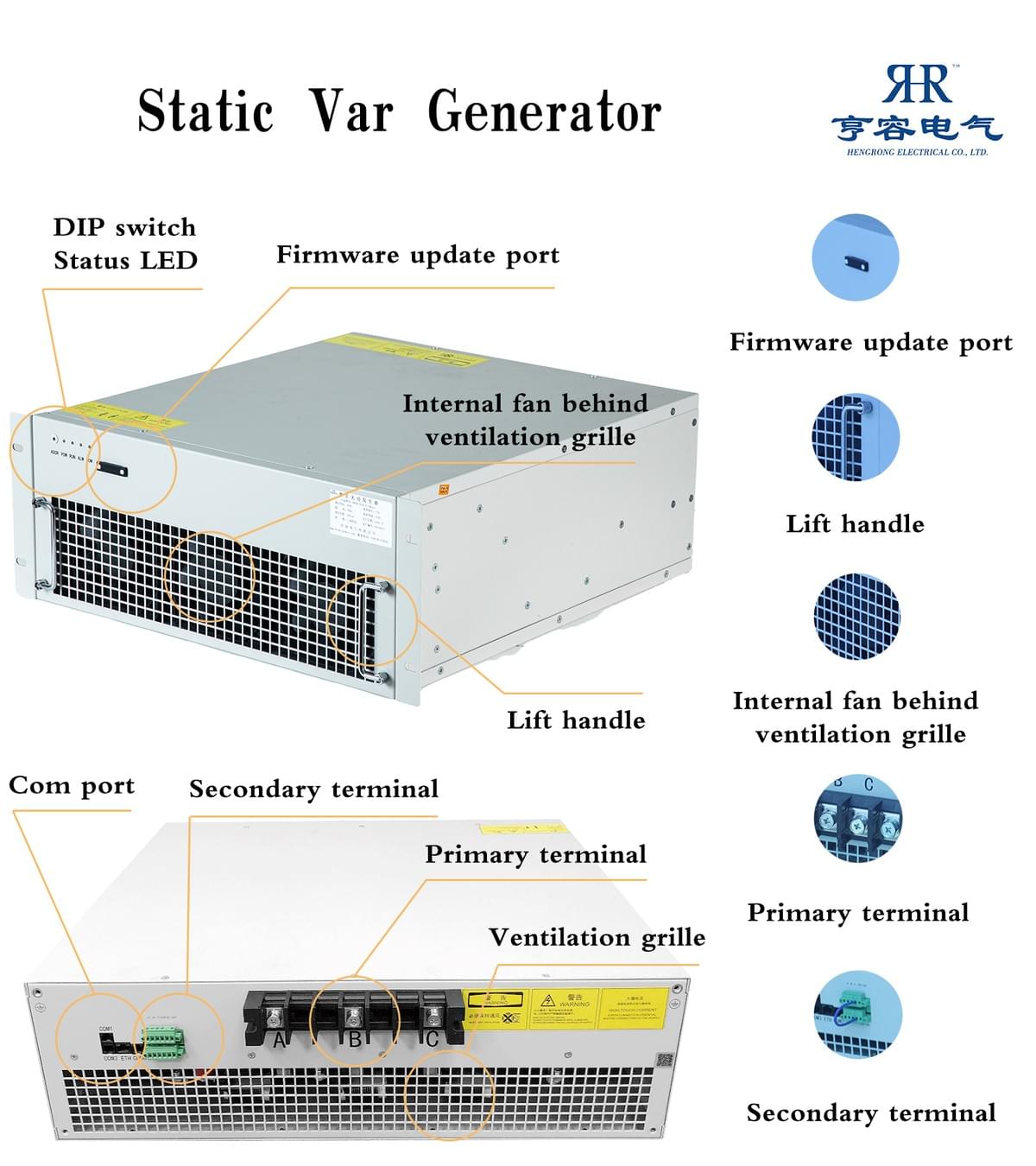

An SVG continuously monitors the current and voltage of the power system. Through DSP digital control and IGBT modules, it generates a compensation current that cancels out the reactive current from the load. This achieves real-time, dynamic reactive power compensation.

Key advantages of SVG include:

- Fast response: Millisecond-level adjustment to match load fluctuations.

- Accurate compensation: Continuously adjustable output to avoid over- or under-compensation.

- Power quality improvement: Suppresses harmonics and balances three-phase currents.

- Smart operation: Remote monitoring and intelligent control, in line with Smart Grid development.

In short, SVG is not only a compensation device but also an integral part of power quality management in modern energy systems.

Case Study: The Value of SVG in Box-Type Substations

Take an 800kVA box-type substation as an example. During off-season operation, the load drops to around 50kW. Traditional capacitor banks cannot be engaged because each unit has too large a capacity, resulting in a power factor as low as 0.85.

With SVG installed, the compensation current can be adjusted flexibly according to the real-time load, keeping the power factor above 0.95.

This brings multiple benefits:

- Lower electricity costs: Avoiding penalties for low power factor;

- Stable system performance: Reduced voltage fluctuations and equipment overheating;

- Energy saving and loss reduction: Significant decrease in line and transformer losses.

SVG is particularly suitable for industrial enterprises, data centers, renewable energy plants, and integrated energy systems in industrial parks—key application scenarios in the Smart Grid era.

Two Main Paths to Improve Power Factor

1. Deploying SVG (Static Var Generators)

- Real-time, dynamic, and intelligent compensation;

- Precise reactive power control;

- Eliminates common issues of capacitor banks;

- Significant long-term energy-saving results.

2. Optimizing Capacitor Bank Configuration

- Adjusting single-unit capacity and using sequential switching strategies;

- Lower cost for short-term improvement;

- Limited effectiveness under low load or rapidly fluctuating conditions.

Conclusion: SVG is the future-proof solution that aligns with the evolution of the Smart Grid.

Business Value of Deploying SVG

- Energy saving and cost reduction: Power factor maintained above 0.95, reducing penalty fees.

- Longer equipment lifespan: Lower line and transformer losses, reducing maintenance costs.

- Improved reliability: Stable supply during motor startups and sudden load changes.

- Sustainability and branding: Supports corporate ESG goals, enhancing green and smart enterprise image.

Conclusion: SVG Empowering Smart Grid and Sustainable Development

With the rise of the Smart Grid and global energy transformation, SVG Static Var Generators are gradually replacing traditional capacitor banks as the core technology for improving power factor and power quality in box-type substations.

From manufacturing and data centers to renewable energy plants, SVG enables enterprises to achieve energy saving, stable supply, and sustainable growth.

Looking ahead, as SVG technology becomes more cost-effective and widely adopted, it will play an increasingly critical role in supporting the Smart Grid and driving energy efficiency across industries.

At Hengrong Electrical, we understand that every detail in power control matters. From advanced product design to innovative filtering solutions, we are committed to delivering reliable, efficient, and future-ready technologies. By choosing Hengrong, you gain more than just products — you gain a trusted partner dedicated to helping your business achieve smarter, safer, and greener operations.