"Design and Simulation Study of a New Type of Reactor" is an academic paper published in Technology Innovation and Application (Issue 28, 2020), jointly completed by researchers from multiple institutions including Hefei Huayao Electronic Industry Co., Ltd., Hefei University of Technology, and Nanjing University. The core authors include Guo Xiang, Mei Chao, and Du Youwei (Member of the Chinese Academy of Sciences). Focusing on the noise problem of dry-type iron-core reactors used in indoor substations in urban areas, the paper proposes and verifies a low-noise three-phase shunt reactor scheme through a complete technical path of "material innovation + structural design + finite element simulation + prototype verification". It provides an engineering technical reference for solving the noise problem of dry-type iron-core reactors, and the full text logically unfolds around "problem tracing - scheme design - simulation verification - experimental implementation". The core content can be divided into five major sections.

1. Research Background and Core Issues: Dilemma of Reactor Noise and Breakthrough Directions

1.1 Core Role of Reactors in Power Grids and Application Trends

With the rapid development of power electronics technology, the requirements for power quality of power grids continue to increase. Reactive power compensation technology, as a key means to improve power quality and enhance the economic benefits of power grids, has long been a research focus in the power system field. Among them, the shunt reactor, as the core electrical device of reactive power compensation technology, has two core functions: first, it effectively compensates for the capacitive effect of transmission lines to avoid line voltage rise; second, it absorbs excess reactive power when the power grid is under light load, ensuring the stability and efficiency of power transmission. In recent years, to meet the "miniaturization and non-pollution" requirements of indoor substations in urban areas, 10kV dry-type iron-core reactors have gradually become the mainstream reactive power compensation equipment. However, the accompanying noise problem has become a key bottleneck restricting their promotion. Indoor environments in urban areas have strict requirements for noise control (usually with a limit of 55-60dB), and the excessive operating noise of traditional reactors not only affects the living and working environments of surrounding residents but also directly restricts their indoor application in densely populated areas.

1.2 Root Causes of Reactor Noise and Limitations of Existing Control Schemes

By sorting out the previous research results of domestic universities, the paper clarifies the core sources of reactor noise. Through experimental research, Professor Han Qiang's research team from South China University of Technology found that the noise of dry-type iron-core shunt reactors mainly comes from iron-core vibration and the magnetostrictive effect of silicon steel sheets under energized conditions: the iron core generates periodic mechanical vibration under the action of an alternating magnetic field; as a traditional iron-core material, silicon steel sheets undergo small periodic deformation (i.e., magnetostriction) in a magnetic field, and this deformation is converted into audible noise with the change of magnetic field frequency, with the magnetostrictive effect being the main cause of noise. The research team led by Fan Chunju from Shanghai Jiao Tong University further verified the direct correlation between iron-core vibration and noise by calculating the vibration modal characteristics of 10kV dry-type transformers through finite element simulation. Yang Yimei from Tianjin Polytechnic University obtained the distribution laws of iron-core magnetic field and vibration under different operating conditions through numerical analysis, providing a theoretical basis for noise control. Liu Ji from Harbin Institute of Technology used finite element software to analyze the magnetic field distribution, magnetostrictive displacement, and sound pressure level of three-phase series iron-core reactors, further confirming that the iron core and silicon steel sheets are the core sources of noise.

However, the previous noise control schemes for reactors in the engineering field were mostly "passive sound insulation", i.e., reducing noise transmission through physical isolation methods such as installing sound insulation enclosures or building sound insulation rooms for reactors. This scheme has two significant drawbacks: first, it does not solve the problem from the "source of noise generation" and can only weaken the noise transmission path, failing to completely eliminate the noise caused by vibration and magnetostriction; second, it additionally increases the manufacturing cost and overall volume of the equipment, which is contrary to the "compact and low-cost" requirements of indoor substations in urban areas. Therefore, there is an urgent need to find a breakthrough direction for active noise reduction from the material or structural level.

1.3 Key to Material Innovation: Advantageous Characteristics of Metal Soft Magnetic Powder Cores

With the development of soft magnetic material technology, magnetic core materials have expanded from traditional silicon steel sheets and ferrites to amorphous materials, nanocrystalline materials, and metal soft magnetic powder cores. Among them, the characteristics of metal soft magnetic powder cores have become the core breakthrough point of this research: this material is composed of iron-based alloy powder and an insulating material coated on the surface of the magnetic powder, and has two core advantages that are suitable for noise control needs: first, its magnetostriction coefficient and magnetocrystalline anisotropy constant are close to zero, which can significantly reduce iron-core vibration from the source and avoid noise caused by magnetostriction; second, the insulating coating on the surface of the magnetic powder can effectively isolate eddy currents, ensuring that the magnetic components still maintain good electrical performance even in power grid environments with high-order harmonics, and avoiding additional heat generation and noise caused by eddy current loss intensification. Based on this material characteristic, the paper proposes a "hybrid magnetic circuit" design idea - combining the high magnetic permeability advantage of silicon steel sheets with the low-noise advantage of metal soft magnetic powder cores to construct a new reactor iron-core structure, thereby solving the noise problem from the source.

2. Design Scheme of the New Three-Phase Shunt Reactor: Material, Parameters, and Structural Innovation

The core object designed in the paper is a 260kVA, 10kV power frequency three-phase shunt reactor. The design process focuses on the dual goals of "meeting electrical performance requirements + noise control", and forms an implementable technical scheme through material selection, parameter calculation, and structural optimization.

2.1 Design Principles and Material Selection Logic

The core principle of the design is "function adaptation": according to the functional requirements of different parts of the reactor, differentiated materials are selected to balance magnetic permeability and low-noise characteristics. The specific selection is as follows:

- Yoke material: The core function of the yoke is to guide magnetic flux and reduce magnetic circuit loss, so a material with high magnetic permeability needs to be selected. The paper uses 30Q130 silicon steel sheets with a thickness of 0.3mm. This type of silicon steel sheet has high saturation magnetic flux density and low loss characteristics, which can effectively reduce the magnetic resistance of the magnetic circuit, reduce magnetic flux leakage, and adapt to the functional positioning of the yoke as a "magnetic flux conductor".

- Magnetic column material: The magnetic column is the main area where iron-core vibration and noise are generated, so the magnetostrictive effect must be prioritized. The paper uses a metal soft magnetic powder core with an effective permeability of 60. Its low magnetostriction coefficient can suppress vibration from the source, and the insulating coating can isolate eddy currents to avoid additional loss under high-order harmonics.

- Magnetic flux density control: To avoid increased loss and intensified noise caused by magnetic saturation, combined with the magnetic characteristics of soft magnetic materials, the maximum operating magnetic flux density of the iron core is clearly set to not exceed 1T in the design. This value not only ensures the utilization rate of the material's magnetic properties but also avoids the enhancement of the magnetostrictive effect caused by magnetic saturation.

2.2 Derivation and Determination of Key Design Parameters

Through three core formulas and combined with engineering empirical coefficients, the paper derives the key dimensions and electrical parameters of the reactor to ensure that the design meets the rated operating conditions of 10kV and 260kVA:

- Iron core diameter calculation: The formula \(D_{0}=K_{d} \times \sqrt[4]{P / 3}\) is used, where \(P\) is the rated capacity of the reactor (260kVA), and \(K_{d}\) is an empirical coefficient related to the material of the current-carrying conductor (taking the commonly used empirical value in the industry according to the conductive characteristics of enameled copper wires). The final calculated magnetic column diameter is adapted to the overall iron-core structure.

- Single-turn winding electromotive force calculation: The formula \(e_{0}=\frac{4.44 fNB_{c}A_{c} \times 10^{-4}}{N}\) is used (which can be simplified to derive the relationship between the number of winding turns and magnetic flux density), where \(f\) is the power frequency (50Hz), \(N\) is the number of turns per column winding, \(B_{c}\) is the maximum operating magnetic flux density of the iron core (≤1T), and \(A_{c}\) is the effective cross-sectional area of the iron core. Through this formula, combined with the 10kV rated voltage requirement, the number of turns per column winding is calculated to be 1050, ensuring that the winding electromotive force matches the grid voltage.

- Air gap length calculation: The formula \(l_{g}=K_{f} \times(\frac{NI}{B \times 10^{4}}-\frac{l_{c}}{\mu_{m}})\) is used, where \(K_{f}\) is an empirical coefficient (selected according to the design requirements of distributed air gaps), \(l_{c}\) is the total length of the magnetic circuit, \(\mu_{m}\) is the effective permeability of the material (60 for the metal soft magnetic powder core), \(N\) is the number of turns, and \(I\) is the rated current (design value of 15A). The final calculated total air gap length of the magnetic column is 46mm. To reduce magnetic flux leakage and eddy current loss, a "distributed air gap" design is adopted - the 46mm air gap is divided into 4 segments (8mm, 12mm, 12mm, 14mm) and evenly distributed on the magnetic column, replacing the traditional "concentrated air gap", which effectively reduces the magnetic flux leakage density at the air gap and avoids the increase in winding eddy current loss caused by magnetic flux leakage.

2.3 Complete Definition of Core Design Parameters

Through the above formula calculation and engineering optimization, the paper finally determines the complete design parameters of the reactor, covering three dimensions: electrical performance, material characteristics, and structural dimensions, providing a clear basis for subsequent simulation and prototype manufacturing:

- Electrical parameters: Rated voltage of 10kV (adapting to the voltage level of indoor substations in urban areas), rated capacity of 260kVA (meeting the reactive power compensation needs of medium and low-voltage distribution networks), designed inductance of 1H (ensuring the reactive power compensation effect meets the standard), number of turns per column winding of 1050 (matching the 10kV voltage and 50Hz power frequency), and rated current design value of 15A (derived from capacity and voltage).

- Material parameters: Yoke made of 30Q130 silicon steel sheets (0.3mm thick, high magnetic permeability), magnetic column made of metal soft magnetic powder cores (effective permeability of 60, low magnetostriction), and winding wire made of enameled copper wire QZB 2×4 (low resistivity, reducing copper loss).

- Structural parameters: Overall iron-core size of 1180×1040×200mm (adapting to indoor installation space), winding height of 550mm (balancing heat dissipation needs and space occupation), single-segment size of the magnetic column of 700×200×200mm (matching the yoke size to ensure smooth magnetic flux conduction), winding inner diameter of 325mm, and outer diameter of 440mm (optimized according to the magnetic column size and number of turns to avoid electromagnetic interference between windings).

3. Finite Element Simulation Analysis Based on ANSYS Maxwell: Verifying Design Feasibility

To ensure the electrical performance and rationality of the design scheme, the paper uses ANSYS Maxwell 3D finite element simulation software (a mainstream electromagnetic field simulation tool in the power electronics field) to comprehensively evaluate the operating characteristics of the reactor through modeling, meshing, and multi-dimensional performance analysis, providing theoretical support for prototype manufacturing.

3.1 Simulation Software Principle and Modeling Assumptions

ANSYS Maxwell conducts simulations based on the "finite element idea": discretizing the continuous 3D structure of the reactor into a limited number of independent elements, setting nodes in each element, describing the distribution law of the electromagnetic field in the element through interpolation functions, and then establishing a finite element equation set for the unknown quantities at the nodes, converting the "infinite degree of freedom" electromagnetic field problem into a "finite degree of freedom" numerical solution problem. This software supports multiple solution modules such as static magnetic field, eddy current field, and transient field, and has excellent finite element calculation capabilities and multi-physics field coupling capabilities. It is widely used in the simulation verification of electromagnetic equipment such as transformers, reactors, and motors, and has mature applications in fields such as power grids, automobiles, and aerospace.

To be close to actual operating conditions and simplify the calculation complexity, the paper sets three reasonable assumptions during the modeling process: first, the excitation source is a standard sine wave, and the influence of high-order harmonics is temporarily not considered - after harmonic control in urban power grids, the content of high-order harmonics is low (usually ≤5%), which has little impact on the overall performance of the reactor; second, the properties of the iron-core air gap spacer are similar to air - the air gap spacer is a non-magnetic insulating material, whose magnetic permeability is close to that of air, and its impact on the magnetic field distribution can be ignored; third, displacement current is ignored - under the power frequency (50Hz), the displacement current is much smaller than the conduction current, and its impact on the reactor current and loss calculation can be ignored. At the same time, to ensure the accuracy of the simulation results, the modeling adopts a "1:1 scale", and all structural dimensions are completely consistent with the design parameters, including the dimensions of the yoke, magnetic column, and winding, as well as the distribution mode and length of the air gap.

3.2 Meshing: Core Guarantee for Simulation Accuracy

The density and rationality of meshing directly determine the accuracy of simulation results. The paper adopts a strategy of "adaptive meshing + local refinement" to balance calculation accuracy and efficiency:

- Overall meshing strategy: Based on the software's adaptive meshing algorithm, the TAU mode is used as the meshing element. The TAU mode element has good geometric adaptability and can accurately fit the complex structure of the reactor (such as the cylindrical structure of the winding and the segmented structure of the air gap), avoiding calculation errors caused by unreasonable element shapes.

- Local refinement scheme: Differentiated refinement is carried out according to the electromagnetic field characteristics of different parts of the reactor: first, the iron core is refined, with the maximum mesh element side length set to 5mm - the iron core is the core area of the electromagnetic field, where magnetic flux density and magnetostriction are concentrated, and high mesh accuracy is required to ensure accurate calculation; second, the air gap is focused on refinement, with the maximum mesh element side length set to 0.5mm - the magnetic field gradient at the air gap is large, and magnetic flux leakage and eddy current loss are sensitive to mesh accuracy. After refinement, the magnetic flux diffusion phenomenon at the air gap can be accurately captured, avoiding loss evaluation deviations caused by magnetic flux leakage calculation errors.

3.3 Multi-Dimensional Simulation Result Analysis: Verifying Design Compliance

The paper analyzes the simulation results from four core dimensions (inductance, induced current, magnetic flux density, and loss) to comprehensively verify the feasibility of the design scheme:

3.3.1 Inductance Analysis: Core Electrical Indicators Meet Standards

Inductance is the core indicator for the reactor to realize the reactive power compensation function. The simulation results show that when the applied voltage is a 10kV sine wave, the reactor inductance first undergoes a short-term unbalanced state (within approximately 10ms) and then enters a stable fluctuation range. Among them, the average inductance of phase A is about 1.0536H, phase B is about 1.0365H, and phase C is about 1.0290H. The average inductance of the three phases is close to the designed value of 1H, with a fluctuation range of 0.98-1.09H and a fluctuation amplitude of less than 10%. This result indicates that the magnetic circuit design of the reactor is stable, there is no magnetic saturation phenomenon, and the inductance meets the performance requirements of reactive power compensation, verifying the rationality of the magnetic circuit structure and air gap design.

3.3.2 Induced Current Analysis: Circuit Characteristics Meet Expectations

The waveform and value of the induced current directly reflect the circuit characteristics of the reactor. The simulation results show that the three-phase induced current presents a standard sinusoidal distribution, with no obvious distortion (distortion rate ≤3%), and the phase difference between the three phases A, B, and C is strictly maintained at 120°, which conforms to the symmetry requirements of three-phase circuits. In terms of values, the effective value of phase A current is 14.5576A, phase B is 14.7111A, and phase C is 15.1415A. The error from the designed value of 15A is less than 4%, which is within the engineering allowable range (usually ≤5%). This result indicates that the winding turn design, wire selection, and structural dimensions are matched, and there are no obvious parasitic parameters (such as distributed capacitance and leakage inductance) affecting the current characteristics, and the circuit design meets expectations.

3.3.3 Magnetic Flux Density Analysis: Reasonable Magnetic Circuit Distribution

The distribution of magnetic flux density directly affects iron-core loss and noise risk. In the simulation, the moment when the coil current of the middle column reaches the maximum value (when the magnetic flux density is the highest) is selected for analysis. The results show that the maximum magnetic flux density of the middle column iron core is about 0.85T, which is lower than the designed limit of 1T, avoiding increased loss and intensified noise caused by magnetic saturation; the magnetic flux is mainly concentrated in the middle column and the side columns on both sides, and the magnetic flux density of the upper and lower yokes is low (about 0.3-0.5T), which conforms to the design original intention of "the yoke guides magnetic flux and the magnetic column bears the main magnetic flux"; due to the non-magnetic characteristics of the air gap, slight magnetic flux diffusion (magnetic flux leakage) occurs at the air gap. However, due to the adoption of the distributed air gap design, the range of magnetic flux leakage is effectively controlled, and the magnetic flux leakage density is lower than 0.2T, which does not cause a significant increase in winding eddy current loss.

3.3.4 Loss Analysis: Economical and Reasonable Loss Distribution

The loss of the reactor is mainly divided into "iron loss" (hysteresis loss and eddy current loss of the iron core) and "copper loss" (resistance loss of the winding). The simulation results show that the average iron loss is 1.0564kW, the average copper loss is 2.6304kW, and the total loss is 3.6868kW. From the perspective of loss distribution, the proportion of copper loss in the total loss is about 71.3%, and the proportion of iron loss is about 28.7%. The high proportion of copper loss is due to the high current density of the winding (meeting the current demand of 10kV and 260kVA capacity), while the low iron loss benefits from the low-loss characteristics of the metal soft magnetic powder core. The overall loss level meets the industry standard for 260kVA capacity reactors (usually total loss ≤4kW), with no abnormal loss points, verifying the economy and rationality of the design.

4. Prototype Manufacturing and Performance Testing: Experimentally Verifying the Feasibility of the Scheme

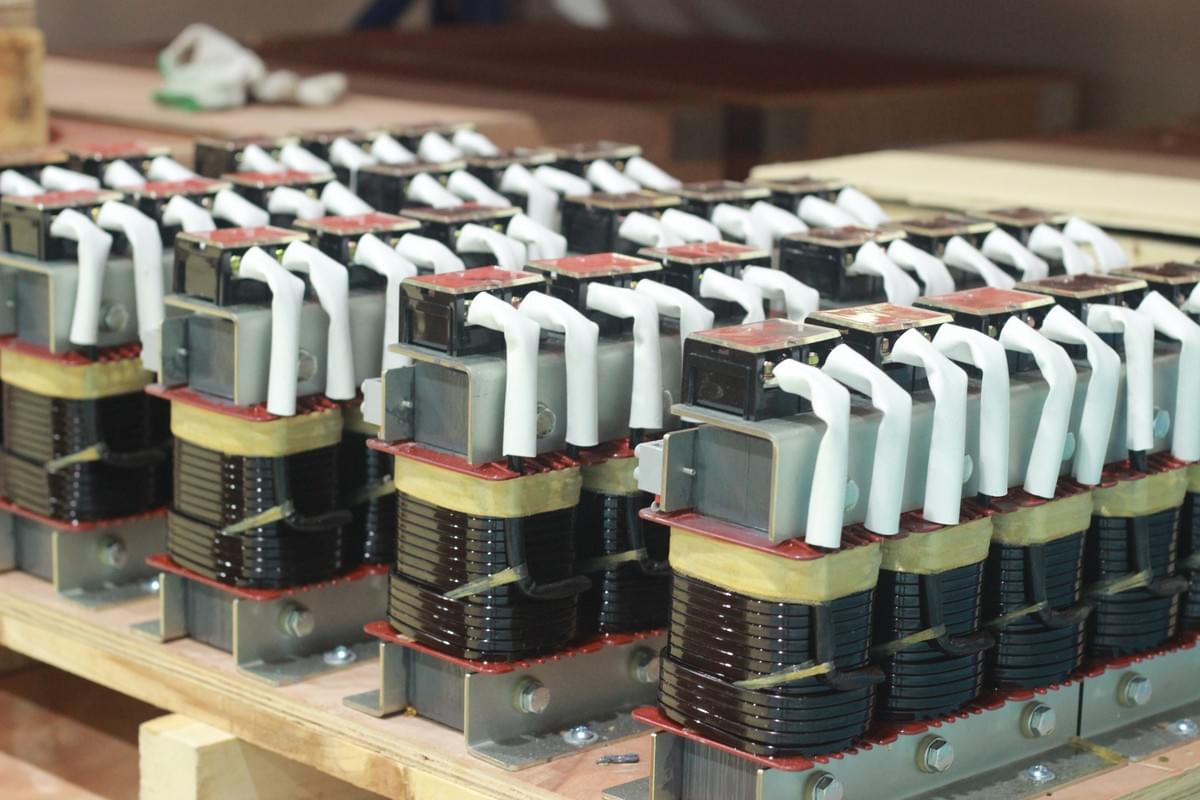

Based on the design parameters and simulation analysis results, the paper manufactured a 260kVA, 10kV three-phase shunt reactor prototype, and conducted electromagnetic performance and noise tests in a laboratory environment to experimentally verify the feasibility of the scheme.

4.1 Process Control for Prototype Manufacturing

The prototype manufacturing process strictly follows the design parameters, with key control over three core processes: first, the iron-core assembly process - the yoke is stacked with 30Q130 silicon steel sheets, and the stacking factor is controlled above 0.92 (to ensure the magnetic permeability meets the standard); the magnetic column is made by pressing metal soft magnetic powder cores, and the fitting gap with the yoke is controlled within 0.1mm (to reduce the air gap loss of the magnetic circuit). Second, the winding winding process - enameled copper wire QZB 2×4 is used, and the tension is controlled uniformly during the winding process (to avoid changes in resistivity caused by wire stretching); the turn accuracy is controlled within ±1 turn (to ensure the inductance meets the standard); the winding ends are fixed with insulating materials (to avoid noise caused by vibration). Third, the air gap setting process - according to the designed distributed air gap scheme, 4 segments of air gaps are accurately processed on the magnetic column, the length error of each segment of air gap is controlled within ±0.5mm, and the air gap spacers are made of insulating ceramic materials (to ensure non-magnetism and high-temperature resistance).

4.2 Electromagnetic Performance Testing: High Consistency Between Simulation and Experiment

Under the test conditions of rated voltage 10kV and power frequency 50Hz, a high-precision power analyzer (accuracy class 0.1) was used to measure the total loss of the prototype. The results show that the measured total loss of the prototype is 3.7634kW. Compared with the simulated total loss (3.6868kW), the error is about 2%, which is far lower than the engineering allowable error of 5%. This indicates that the ANSYS Maxwell simulation model has high accuracy and can effectively predict the loss characteristics of the reactor; at the same time, the measured average inductance of the three phases is 1.03H, with an error of about 3% from the designed value of 1H; the measured average effective value of the three-phase current is 14.9A, with an error of about 0.7% from the designed value of 15A. All electrical parameters meet the design requirements, verifying the rationality of the design and simulation.

4.3 Noise Testing: Significant Low-Noise Advantage

A precision sound level meter (accuracy class 1) was used for noise testing. In a semi-anechoic chamber environment (background noise ≤30dB), noise values were collected at 4 measuring points 1m around the prototype, and the average value was taken as the final result. The test shows that the noise level of the prototype under the rated voltage of 10kV is 54.3dB, which is lower than the noise limit of indoor environments in urban areas (55-60dB) and meets the indoor use requirements; while the noise level of traditional pure silicon steel iron-core reactors with the same capacity is usually about 70dB, and the noise reduction amplitude of the new reactor is about 16dB, showing a significant noise reduction effect. The core reason for the noise reduction is that the magnetostriction coefficient of the metal soft magnetic powder core is close to zero, which weakens the iron-core vibration from the source and avoids the noise caused by the magnetostriction of traditional silicon steel sheets, verifying the effectiveness of the material innovation scheme.

5. Research Conclusions and Value: Technical Contributions and Engineering Significance

5.1 Core Research Conclusions

- Effective Structural Innovation: The hybrid magnetic circuit design of "silicon steel sheet yoke + metal soft magnetic powder core magnetic column" not only retains the advantages of high magnetic permeability and low magnetic resistance of silicon steel sheets but also suppresses noise from the source through the low magnetostriction characteristics of metal soft magnetic powder cores. Compared with traditional passive sound insulation schemes, it realizes "active noise reduction" with a noise reduction amplitude of 16dB, without increasing the equipment volume and cost.

- Reliable Simulation Tool: ANSYS Maxwell 3D finite element simulation software can accurately predict the inductance, induced current, magnetic flux density, and loss of the reactor, with a loss error of only 2% between simulation and experiment. It can be used as an efficient tool for reactor optimization design, reducing the number of iterations of physical prototypes and lowering R&D costs.

- Engineering Feasibility of the Scheme: The electrical performance (inductance, current, loss) and noise indicators of the prototype all meet the design requirements. The noise level of 54.3dB meets the indoor use requirements in urban areas, and the total loss conforms to industry standards. The scheme can be directly applied to the reactive power compensation scenario of 10kV indoor substations in urban areas.

5.2 Technical Value and Limitations of the Research

- Engineering Value: The paper applies metal soft magnetic powder cores to the magnetic column design of 10kV dry-type iron-core shunt reactors for the first time, and proposes a technical scheme of "hybrid magnetic circuit + distributed air gap", providing an implementable technical path for noise control of dry-type iron-core reactors and filling the technical gap in the application of low-noise reactors in indoor urban substations. At the same time, the established closed-loop process of "design - simulation - testing" provides a paradigm reference for the R&D of similar low-noise electromagnetic equipment.

- Typesetting and Research Limitations: The paper has a typesetting defect - irrelevant content about "intelligent flower maintenance machine for 'flower therapy'" appears after page 31, and then the reactor research continues with the note "continued from page 31". The irrelevant content does not affect the integrity of the core technical content; the research limitation is that the prototype is only designed for the 260kVA capacity, and future research can be extended to reactors with larger capacities (such as 500kVA, 1000kVA) to further verify the universality of the scheme.

6. Conclusion

"Design and Simulation Study of a New Type of Reactor" breaks through the noise bottleneck of traditional reactors through material innovation. With metal soft magnetic powder cores as the core, combined with hybrid magnetic circuit design, finite element simulation, and prototype verification, it forms a complete technical scheme for low-noise reactors. The research not only clarifies the noise suppression mechanism of metal soft magnetic powder cores in theory but also verifies the engineering feasibility of the scheme through experiments. Its achievements are of great significance for promoting the application of low-noise reactors in indoor urban substations and also provide a "material innovation + simulation-driven" technical idea for the R&D of low-noise equipment in the power electronics field.

Hengrong Electric Co., Ltd.

We specialize in providing high-efficiency reactive power compensation and power quality optimization solutions. With over 20 years of industry experience, our products excel in enhancing grid efficiency, reducing energy consumption, and ensuring system stability.

Our core products and services include:

Low-voltage Reactive Power Compensation and Power Quality Optimization:

Self-healing Capacitors:

Improve power factor, optimize grid power quality, and extend equipment lifespan with self-healing functionality.

Increased Safety Capacitors:

Designed for hazardous environments with combustible gases, providing high safety and explosion-proof features.

Tuned Reactors:

Effectively absorb grid harmonics, improve voltage waveform stability, and protect capacitors.

Composite and Thyristor Switches: Reliable capacitor switching devices with no inrush current, low noise, and stable operation.

High-voltage Reactive Power Compensation Solutions:

High-voltage Capacitors and Reactors: Enhance high-voltage grid stability, effectively compensate reactive power, and suppress harmonics.

Power Quality Governance:

Active Power Filters (APF):

Eliminate harmonics, improve power quality, and ensure system stability.

Static VAR Generators (SVG):

Provide dynamic reactive power compensation with fast and smooth system response.

Smart and Customized Solutions:

Offer smart power quality management controllers and intelligent compensation devices that adapt to complex grid environments, ensuring optimal operation.

Why Choose Hengrong Electric?

Industry Experience: We have extensive experience in power quality optimization, having delivered reliable solutions for numerous clients across various industries.

Customized Services: We provide tailored solutions based on specific client needs, ensuring the maximum benefits for every project.

Technical Assurance: Our products are internationally certified and feature advanced technology, ensuring high efficiency, reliability, and long-term stability.