Amid the continuous global surge in energy demand and the increasing complexity of power grid structures, the low-voltage power grid, as the "last mile" of power supply, directly impacts industrial production efficiency and residential electricity experience. However, issues such as reduced power factor and increased energy consumption caused by reactive power have long been core pain points in the optimization and upgrading of low-voltage power grids. As a key solution to this challenge, reactive power compensation technology is undergoing a revolutionary transformation driven by intelligent technological advancements. The emergence of intelligent power automation compensation technology not only makes reactive power compensation more precise and efficient but also serves as a crucial pillar for enterprises to achieve power factor correction and contribute to carbon neutrality goals.

## The Core Value of Reactive Power Compensation: Beyond Power Optimization, a Key to Green Transformation

When it comes to reactive power compensation, many first think of improving power quality, but its value extends far beyond that. In low-voltage power grids, the presence of reactive power increases the effective value of current, leading to higher line losses, reduced utilization of power equipment, and even voltage fluctuations that affect the normal operation of sensitive devices. Effective reactive power compensation balances reactive power, bringing the power factor closer to the ideal state, fundamentally reducing grid losses, and enhancing the economic operation of the power system.

For enterprises, reactive power compensation is directly related to operational costs and compliance risks. Failure to meet power factor standards may result in fines from power supply authorities. However, by achieving power factor correction through scientific reactive power compensation, enterprises can not only avoid such fines but also fully unlock the capacity potential of power equipment and reduce unnecessary power investments. From a broader perspective, the energy-saving and consumption-reducing effects of reactive power compensation represent an important practical path for enterprises to respond to the carbon neutrality strategy and reduce carbon emissions, transforming power usage from an "extensive" to an "intensive" model.

Although traditional reactive power compensation technologies have played a role in specific scenarios, their limitations—such as low intelligence and slow response speeds—make them unable to adapt to the ever-changing power operating conditions of today. The rapid advancement of industrial automation has imposed increasingly stringent requirements on power quality, and traditional technologies can no longer meet the demand for real-time dynamic compensation. This has driven the in-depth application of intelligent power automation compensation technology in the field of reactive power compensation.

## Intelligent Power Automation Compensation Technology: Reshaping the Core Logic of Reactive Power Compensation

The reason why intelligent power automation compensation technology can achieve a leapfrog upgrade in reactive power compensation lies in its integration of advanced sensor technology, intelligent control algorithms, and power electronics technology, forming a complete closed loop of "real-time monitoring - precise analysis - dynamic compensation." Based on power electronic devices, this technology continuously monitors reactive power in the low-voltage power grid, automatically adjusts the output of compensation devices, and maintains dynamic balance of reactive power at all times, transforming reactive power compensation from "passive response" to "proactive prediction."

In terms of the precision of reactive power compensation, the optimal control of intelligent algorithms plays a key role. Fuzzy control algorithms take reactive power deviation and its rate of change as core inputs, and through flexible fuzzy rules, real-time adjust the output ratio of compensation devices to ensure the power factor quickly approaches the ideal value. Neural network control algorithms, by learning massive amounts of power system operation data, establish a non-linear relationship between reactive power and compensation strategies, significantly improving the control precision of reactive power compensation and system stability. The collaborative application of these two algorithms enables reactive power compensation to accurately adapt to reactive power demands under different load changes and operating conditions, completely solving the problem of insufficient compensation precision in traditional technologies.

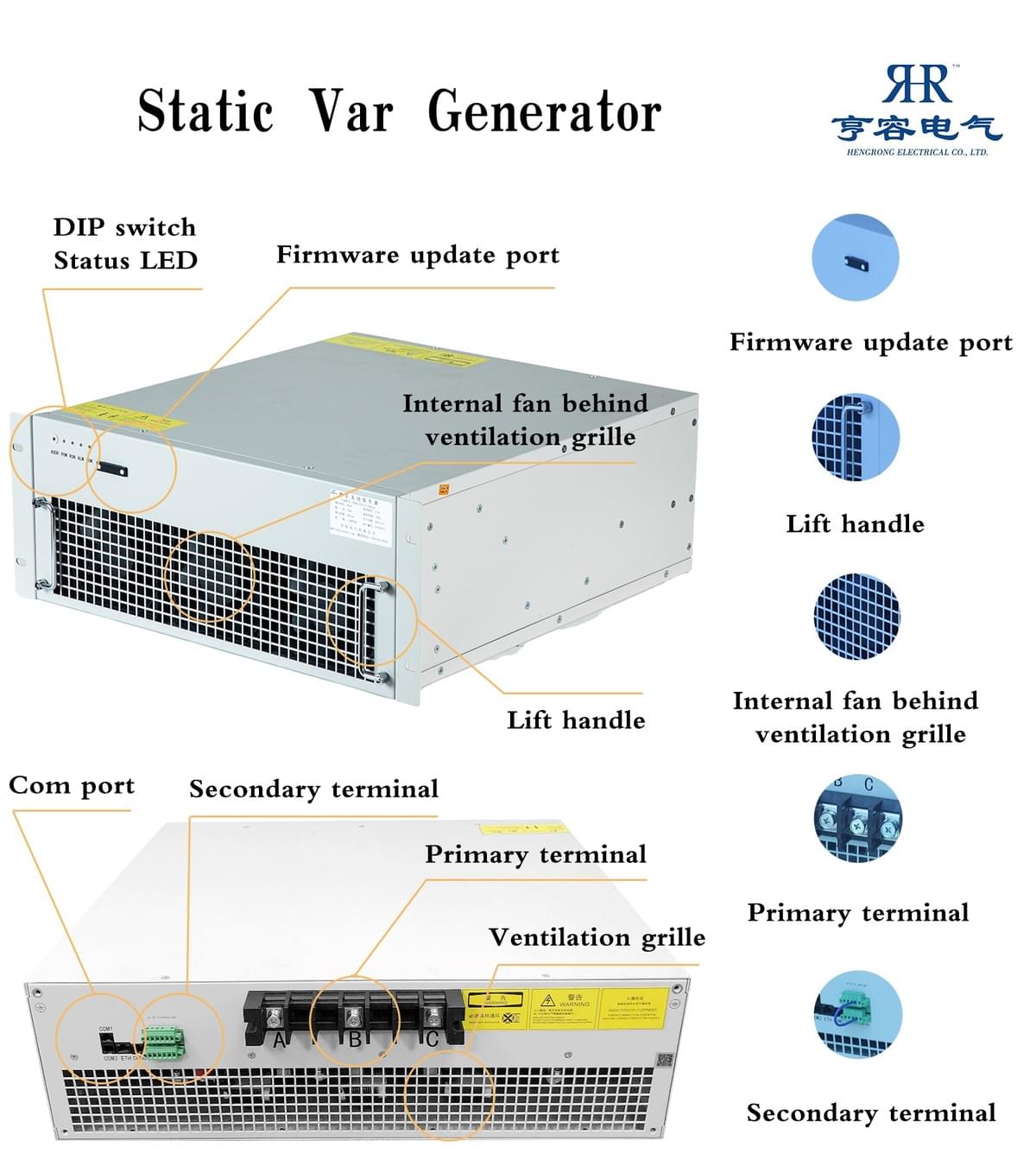

The flexible application of Static Var Compensators (SVC) and Static Var Generators (SVG) further expands the applicable scenarios of reactive power compensation. SVC achieves continuously adjustable reactive power absorption through the coordinated operation of thyristor-controlled reactors and switched capacitors. SVG, based on fully controlled power electronic devices, can respond to changes in grid reactive power within milliseconds, realizing continuous compensation adjustment from 0 to rated capacity. The application of these two devices allows intelligent power automation compensation technology to cover various low-voltage power consumption scenarios such as industrial production and commercial complexes, providing customized reactive power compensation solutions for enterprises of different sizes and types.

The integrated use of sensor data is an important guarantee for the precision of reactive power compensation. Low-voltage reactive power compensation systems integrate high-precision voltage transformers and current transformers to comprehensively capture amplitude and phase information of grid voltage and current. After signal processing, this data is transmitted to processors for analysis, providing reliable data support for reactive power compensation decisions. This multi-dimensional and high-precision data collection and integration capability ensures that reactive power compensation is no longer dependent on empirical judgment but is based on scientific quantitative analysis, guaranteeing that every compensation action is precise and efficient.

## Practical Empowerment of Reactive Power Compensation: From Enterprise Benefits to Sustainable Industry Development

The application of intelligent power automation compensation technology in low-voltage reactive power compensation has demonstrated significant value in numerous scenarios. In industrial production settings, this technology effectively reduces the transmission loss of reactive current in power grid lines through precise reactive power compensation, keeping power equipment operating at peak efficiency. It not only improves the stability of production processes but also directly reduces enterprise operating costs through energy conservation and consumption reduction. In large-scale power-consuming venues such as commercial complexes, the reduction in power consumption brought about by reactive power compensation not only eases the cost burden on enterprises but also supports the load balance of urban power grids.

From an industry development perspective, the promotion and application of intelligent power automation compensation technology are driving the standardization and intelligent upgrading of the low-voltage reactive power compensation sector. With the maturity of related technologies and the gradual reduction in costs, more and more small and medium-sized enterprises can access efficient reactive power compensation systems, improving the efficiency of power utilization. This not only helps enhance the operational efficiency of the entire power system and reduce energy waste but also promotes the green and low-carbon transformation of the power industry, injecting sustained momentum into the achievement of global carbon neutrality goals.

As a core link in power system optimization, the technological upgrading and application deepening of reactive power compensation have always kept pace with the development of the energy industry. The emergence of intelligent power automation compensation technology not only addresses the traditional pain points of low-voltage reactive power compensation but also establishes a new paradigm of "precision, efficiency, intelligence, and greenness" for reactive power compensation. In the future, with continuous technological iteration and the expansion of application scenarios, reactive power compensation will play a more significant role in improving power quality, reducing energy consumption, and supporting carbon neutrality, creating greater value for enterprises and providing solid support for the sustainable development of the power industry.

At Hengrong Electrical, we understand that every detail in power control matters. From advanced product design to innovative filtering solutions, we are committed to delivering reliable, efficient, and future-ready technologies. By choosing Hengrong, you gain more than just products — you gain a trusted partner dedicated to helping your business achieve smarter, safer, and greener operations.