In industrial production, the stability and efficiency of power distribution systems are directly related to the continuity and economy of production operations. As a core link in optimizing the performance of power distribution systems, reactive power compensation, with its technical selection and application effects, is a key factor determining the power factor, voltage quality, and equipment lifespan of the power grid. Traditional reactive power compensation schemes are gradually revealing shortcomings in coping with complex working conditions. Breaking through bottlenecks through technological innovation has become an important issue for many enterprises to enhance their power management levels.

I. Dilemma of Traditional Reactive Power Compensation: Why is Capacitor Switching Mode in Urgent Need of Upgrade?

In the field of industrial power distribution, shunt capacitor switching was once the primary method for achieving reactive power compensation. With the basic advantages of improving the power grid's power factor and reducing line losses, it has long served various production scenarios. However, with the iteration and upgrading of industrial equipment, more and more non-linear electrical equipment has been connected to the power grid, and the limitations of traditional reactive power compensation schemes have become increasingly prominent.

On the one hand, harmonics generated during the operation of non-linear equipment can cause pure capacitor banks to frequently experience overheating, overvoltage, partial discharge, and other problems in the process of reactive power compensation. This not only significantly shortens the service life of capacitors but also may cause safety accidents, such as capacitor bulging and explosion, directly leading to the failure of reactive power compensation devices to operate normally. On the other hand, limited by the principle of capacitor switching, traditional schemes are difficult to dynamically track changes in load current, which easily causes fluctuations in the system's power factor and cannot meet the requirements of high-precision reactive power compensation. This further affects the stable operation of production equipment and increases additional power losses and maintenance costs.

As the contradiction between the traditional reactive power compensation mode and modern industrial production becomes increasingly prominent, seeking more reliable and efficient reactive power compensation technology has become an inevitable choice for enterprises to solve power distribution problems and reduce operating costs.

II. SVG Technology: Core Advantages of the New Generation of Reactive Power Compensation Schemes

Facing the pain points of traditional reactive power compensation, the high-voltage static synchronous reactive power compensation device (SVG) has become an ideal solution for upgrading industrial power distribution systems with its excellent performance. As a highly reliable, efficient, and pollution-free power quality management device, SVG not only completely solves the drawbacks of the traditional capacitor switching mode but also redefines the application standards of reactive power compensation through multiple advantages.

1. Millisecond-Level Response for Dynamic Reactive Power Compensation

SVG has a response time of ≤5ms, which can dynamically track the transient changes of load current and complete the compensation of target reactive power in real-time, truly achieving "no lag" adjustment. Whether in scenarios with impact loads or fluctuating loads, SVG can quickly adapt to changes in reactive power demand, avoid fluctuations in power factor, and always maintain the accuracy of system reactive power compensation, providing a solid guarantee for the stable operation of the power distribution system.

2. Diversified Functions for One-Stop Power Quality Solutions

Different from traditional schemes that can only achieve basic reactive power compensation, SVG has the advantage of "one device with multiple uses": it can not only efficiently compensate capacitive and inductive reactive power, stably increasing the grid-side power factor to above 0.98; but also correct the load harmonic current, filter out all or selected harmonics in the range of 2-13th order, and solve the problem of three-phase imbalance at the same time. It realizes the integration of reactive power compensation and power quality management, making the system current purer and the operation more stable.

3. Low Harmonic Pollution to Ensure Power Grid Safety

SVG adopts a carrier phase-shifted PWM control algorithm, and the harmonic content generated by itself is extremely low, which fully meets the harmonic limit requirements of IEEE Std 519-1992 and GB/T 14549-1993. While achieving reactive power compensation, it not only does not cause additional harmonic pollution to the power grid but also can actively optimize the harmonic environment of the power grid, fundamentally eliminating problems such as equipment heating and additional stress caused by harmonics, and extending the service life of power distribution equipment and production equipment.

4. Strong Adaptability to Cope with Complex Working Conditions

SVG has the characteristics of a current source, and the output reactive current is not affected by the bus voltage, and it has a strong short-term overload capacity. Even under complex working conditions such as power grid voltage fluctuations or sudden load changes, SVG can still stably output reactive power, ensuring that the effect of reactive power compensation is not compromised, and further improving the anti-interference ability and operational stability of the power system.

III. Internal Circulation Heat Exchange System: Building a Stable Operation Barrier for Reactive Power Compensation Equipment

As a high-power power quality management device, SVG contains multiple high-power IGBT modules, which have high requirements on the temperature, humidity, and cleanliness of the operating environment. If heat dissipation is not timely or the equipment accumulates dust, it will not only affect the efficiency of reactive power compensation but also lead to SVG failure and shutdown. Therefore, the fully enclosed internal circulation heat exchange system has become a key support to ensure the stable operation of SVG and give full play to the efficiency of reactive power compensation.

Compared with the disadvantage that the traditional ventilation and heat dissipation method is easily affected by the external environment, the internal circulation heat exchange system takes "efficient heat dissipation + dustproof protection" as the core design concept: on the one hand, by arranging cooling fans on the top of the cabinet and setting a fresh air duct around the top of the room, the internal air flow is cycled in a ring shape, maximizing the efficiency of thermal convection and ensuring that SVG is always in the optimal operating temperature range; on the other hand, the fully enclosed structure eliminates the problem of dust being sucked in by the traditional air duct due to negative pressure, effectively protecting the cleanliness of the equipment inside the cabinet and avoiding dust accumulation affecting the performance of reactive power compensation.

At the same time, the system is equipped with an emergency air conditioner indoors as a supplement, further improving the reliability of temperature regulation and providing all-weather environmental protection for SVG to stably realize reactive power compensation for a long time.

IV. Practical Benefits of Reactive Power Compensation Upgrade: Double Improvement in Economy and Safety

An industrial enterprise has achieved a comprehensive upgrade of its power distribution system by introducing the SVG reactive power compensation scheme and the internal circulation heat exchange system. Its practical application fully confirms the value of technological innovation in reactive power compensation.

In terms of economic benefits, before the upgrade, the average power factor of the system was about 0.88, the annual power consumption was about 18.2 million kW·h (industrial electricity was calculated at 0.8 yuan/(kW·h)), and the power adjustment fee to be paid was about 1.456 million yuan. After the upgrade, SVG stably maintained the grid-side power factor above 0.99, which not only completely avoided the fine for power adjustment fees but also reduced line losses due to the improved efficiency of reactive power compensation, saving a large amount of electricity costs every year and significantly shortening the investment return period.

In terms of safety and stability, SVG's perfect fault detection and protection functions provide a guarantee for the reactive power compensation system: the system can automatically identify light and heavy faults. In the case of light faults, it only issues an alarm prompt without affecting the continuous operation of reactive power compensation; in the case of heavy faults, it immediately cuts off the high-voltage power supply and saves fault information, facilitating quick troubleshooting and repair. Since it was put into operation, the current purity of the power distribution system has been significantly improved, problems such as equipment heating and additional stress have been eliminated, the stability of the production line has been significantly improved, and the equipment failure rate and maintenance costs have been greatly reduced.

V. Conclusion: Technological Innovation in Reactive Power Compensation Helps High-Quality Industrial Development

From traditional capacitor switching to SVG dynamic reactive power compensation, from single heat dissipation to an internal circulation heat exchange system, the upgrading of reactive power compensation technology in the field of industrial power distribution is not only a key measure to solve current power distribution problems but also an important path for enterprises to achieve energy conservation and cost reduction and enhance core competitiveness. As industrial production has increasingly higher requirements for power quality, reactive power compensation technology will continue to develop in a more intelligent, efficient, and reliable direction.

In the future, by connecting SVG reactive power compensation devices to the equipment management network to realize intelligent networking and remote monitoring, it will further promote the automation upgrade of industrial power distribution systems and inject a stronger impetus into high-quality industrial development. Choosing the appropriate reactive power compensation scheme is to lay a solid foundation for the stable production and sustainable development of enterprises.

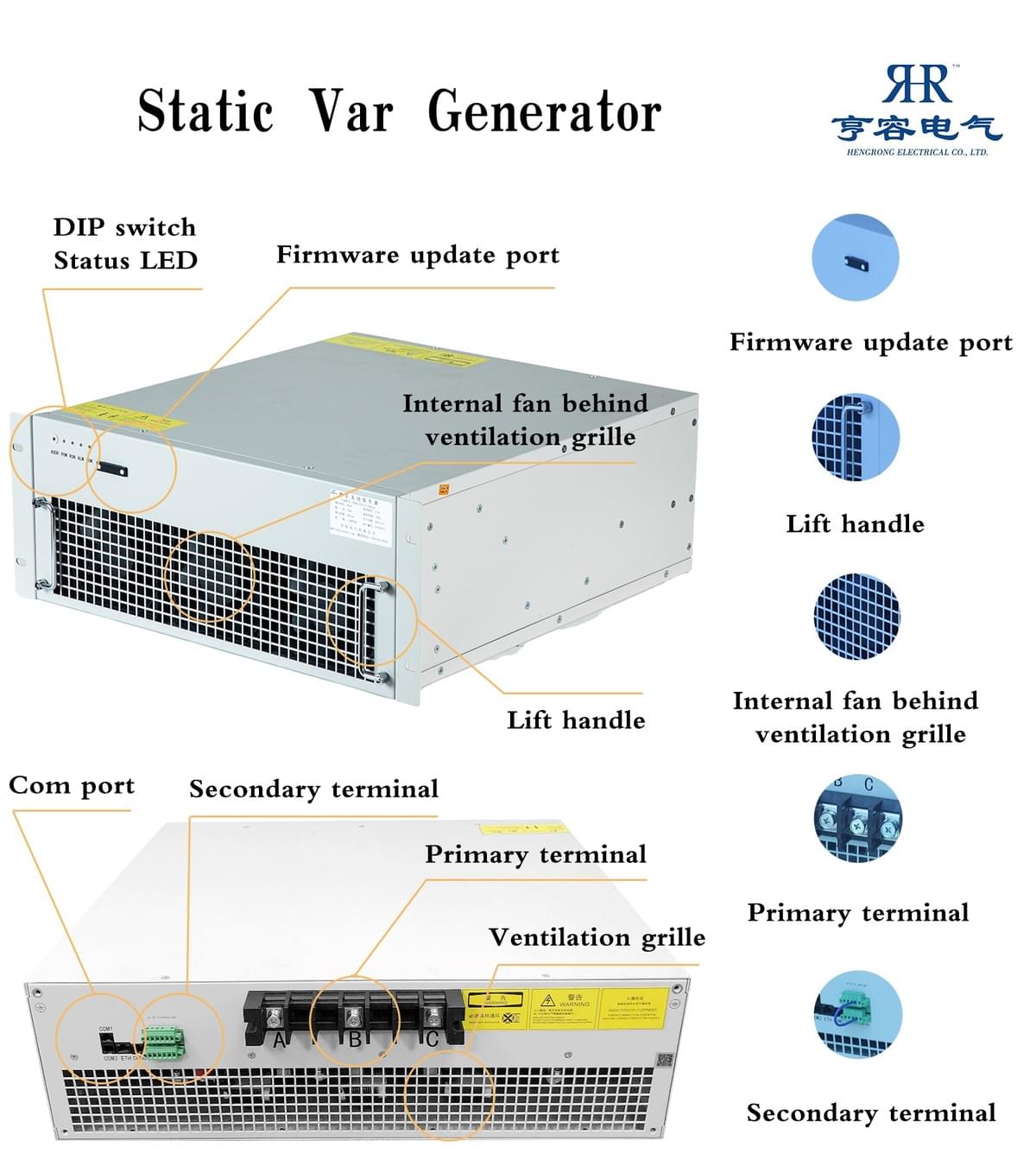

At Hengrong Electrical, we understand that every detail in power control matters. From advanced product design to innovative filtering solutions, we are committed to delivering reliable, efficient, and future-ready technologies. By choosing Hengrong, you gain more than just products — you gain a trusted partner dedicated to helping your business achieve smarter, safer, and greener operations.